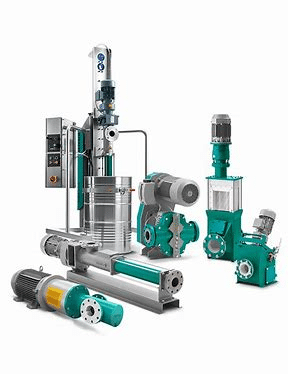

A Progressive Cavity pump (Helical rotor pump) is a type of positive displacement pump also known as an eccentric screw pump or PC pump. The design transfers fluids by means of the progress through the pump. A sequence of small, fixed shape, discrete cavities between the rotor and stator move medium with rotation. This leads to the volumetric flow rate being proportional to the rotation rate with low levels of shear being applied to the pumped fluid. The cavities taper down toward their ends and overlap with their neighbours, so that, in general, no flow pulsing is caused by the arrival of cavities at the outlet. (Other than that caused by compression of the fluid or pump components.) The pump design also has the advantage of being Bidirectional. Progressive Cavity pumps have applications in fluid metering and pumping of viscous or shear-sensitive materials. The applications are endless, from food to sewage, PC pumps have been in the pumping game for years and will always have their place. The diverse design have a proven track record in the movement of SILICONES, PASTES, SLUDGES etc. The NETZSCH high spec. NEMO and TORNADO pumps are made to international manufacturing and hygiene standards and guidelines.

PC pumps can NEVER run dry, NETZSCH offer a run dry protection for the NEMOLAST Stators. These protection units continually monitor the surface temperature of the stator during operation. SHould the operationing temperature rise over a predetermined set point due to an increase in friction caused by dry running, a signal is sent to the motor control unit and shuts the pump down.

Installation of a PC pump can often be suited to the application, end suction, feed hopper or even vertical. Units are available for Food, Pharmaceutical, Chemical and Waste Water however this doesn’t stop here, with a PC pump being positive displacement, if it goes in, it must come out.

Address: 16/10 Olive Road, Penrose, Auckland 1061

Phone: 0800 215 104

Email: sales@pumpworks.co.nz