As the new production year begins, reliability is key for New Zealand industries. With big goals ahead, unexpected downtime is not an option. At Pumpworks, we want to help you get started by checking your pumps and machinery. Consider sending your critical units for a “WOF” (Warrant of Fitness) on our test rig. Many facility managers think a pump is fine as long as it moves fluid, but this is a risky assumption. A pump can cost you money long before it fails completely.

Think of an inefficient pump as an expensive heater that happens to move a bit of water. It draws the same power but wastes a huge chunk of it generating heat instead of flow. This doesn’t just spike your energy bill; it cooks your internal components.

We specialise in finding these invisible issues in your pump and machinery. In this guide, we will show you exactly how to spot the warning signs and make data-backed decisions before a failure stops your line cold.

Performance testing is like a health check for your industrial equipment. It goes further than just looking or listening for problems. We run the pump under controlled conditions to measure how it actually performs. Then, we compare this data to the original manufacturer’s specifications. Every pump comes with a “curve” showing how it should work, but years of use can change that.

This process shows exactly where your equipment is in its lifecycle. We check if the pump meets the needs of your system. It acts as a diagnostic tool. The data tells us what steps to take for your pumps and machinery:

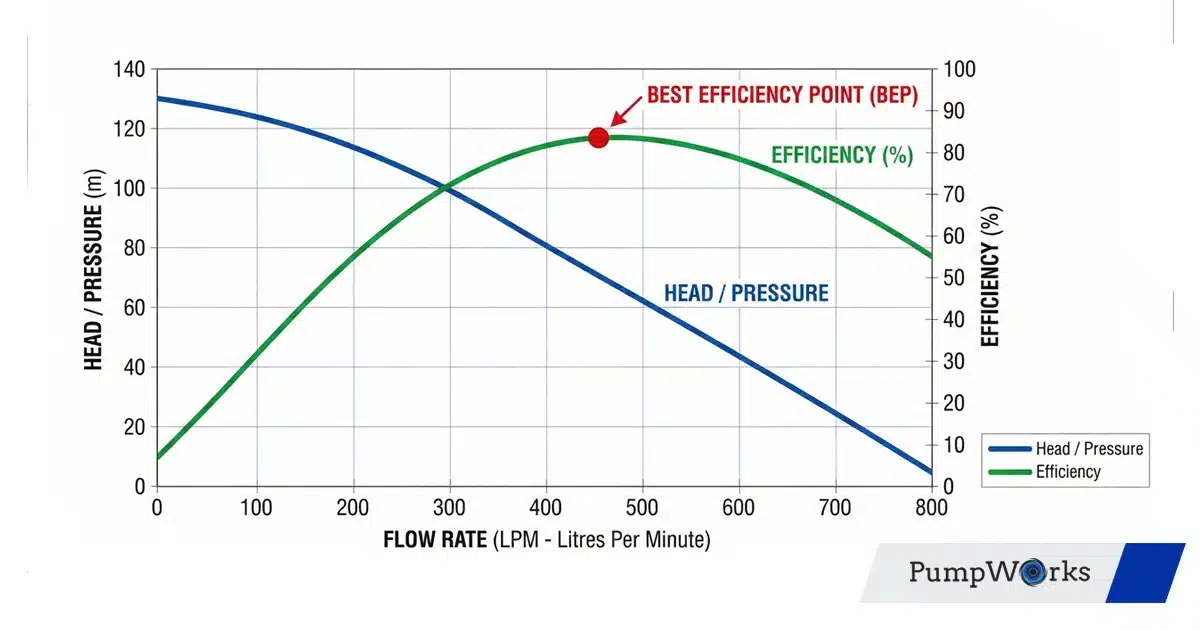

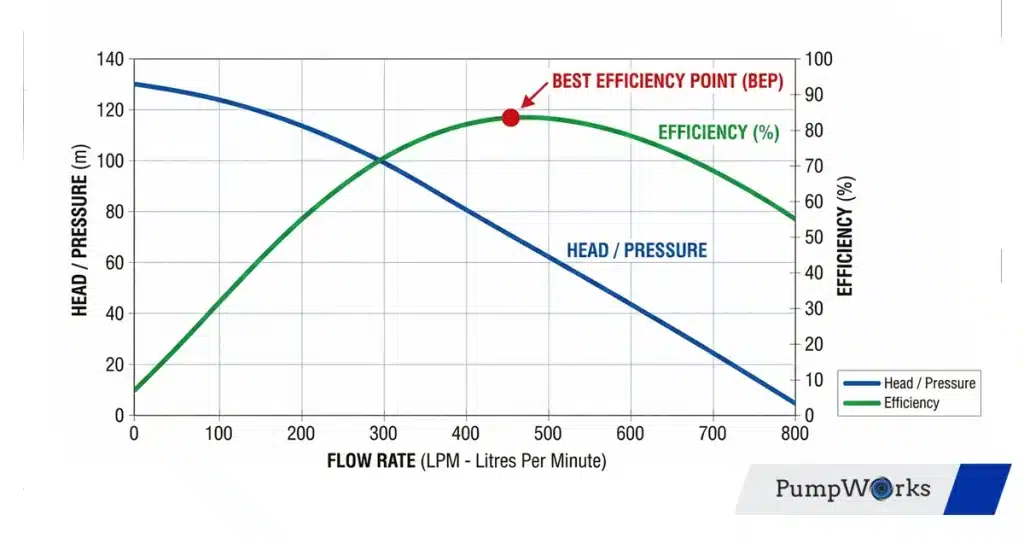

Regular testing of your pump and machinery ensures that your plant operates at the “Best Efficiency Point” (BEP). Operating near the BEP extends the life of bearings and seals while keeping energy bills in check.

We focus on accuracy by testing the pump in a controlled setup. The process has several key steps to make sure we get the right data for your pump and machinery:

Our Penrose facility houses a custom-built test rig designed for accuracy. We invested in this technology to better support our clients. The rig features Variable Speed Drives (VSDs) and high-precision magnetic flow meters. These tools allow us to test a wide range of pump and machinery types.

We can handle everything from small dosing units to large industrial centrifugal pumps. The VSD allows us to test at exact rotational speeds, ensuring the data matches your site conditions perfectly. You get a transparent look at your asset’s health without the guesswork.

Image of a pump performance curve graph showing head vs flow rate and efficiency curves

Understanding the data requires looking at three specific metrics. These indicators tell the full story of hydraulic health. Imagine a graph. The vertical axis represents the head (height/pressure), and the horizontal axis represents the flow.

The “pump curve” is the line that connects these points. We plot your pump’s actual performance against this line. How to evaluate the performance of the pump? You must look at flow, pressure, and power simultaneously.

Flow rate measures the volume of fluid moved over a set time. We typically measure this in Litres Per Minute (LPM) here in New Zealand. The test answers a simple question. Is the pump delivering the volume required for your process?

A drop in flow rate often indicates a blockage or severe wear on the impeller vanes. If your pump and machinery cannot keep up with production demand, flow testing will confirm if the issue lies with the pump or the pipework.

Discharge pressure, or “Head,” refers to the vertical height the pump can lift the fluid. It also relates to the resistance that the pump and machinery can overcome in the pipes. A standard pressure pump must generate enough force to push fluid through filters, heat exchangers, and long pipe runs. If the head pressure drops, the fluid may not reach its destination.

We measure the differential pressure between the suction and discharge ports. This tells us exactly how much energy the pump imparts to the liquid.

We also check how much electrical current the motor uses, measured in Amps. If the amp draw is high, it could mean there’s mechanical drag from bad bearings or a rubbing impeller. If the amp draw is very low, the pump might not be moving any fluid.

Watching power use helps us figure out overall efficiency. We want your pump to do the most work with the least electricity. Efficient pump and machinery setups can save you thousands of dollars in electricity every year.

Pumps are robust, but they are not immune to physics. Efficiency drops naturally as components age. However, specific issues accelerate this decline. Understanding the root causes helps you prevent them.

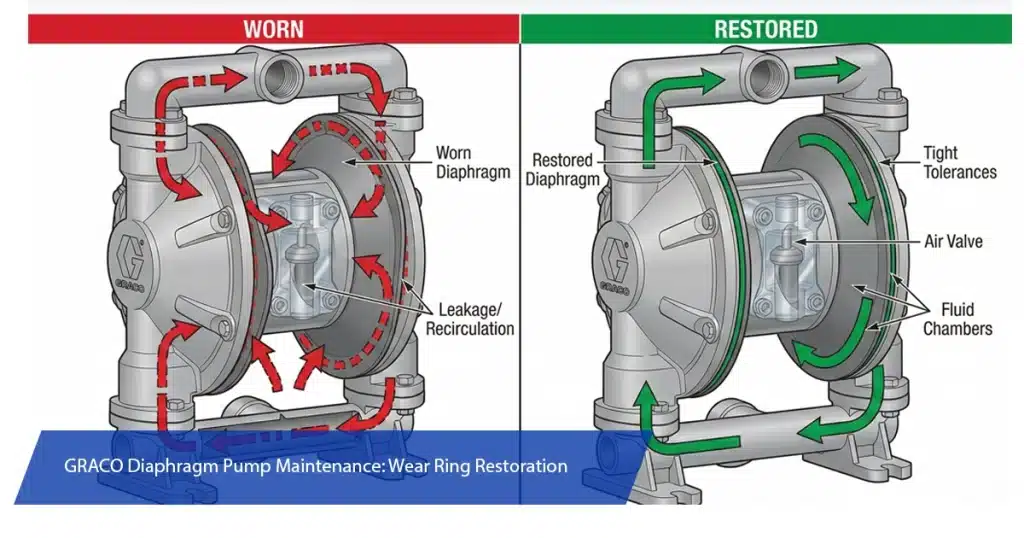

We often find that a pressure pump loses its ability to generate head due to internal clearances opening up. The fluid follows the path of least resistance. If the internal gaps are too wide, the water simply slips back to the suction side instead of exiting the discharge.

Internal recirculation is the most common thief of efficiency. Centrifugal pumps rely on tight tolerances between the impeller and the casing (or wear rings). These gaps act as a seal. Erosion and corrosion widen these gaps over time.

Fluid that should go out the pipe slips back around the impeller. The pump works harder to move the same amount of liquid. We can fix this in our workshop. Replacing wear rings and adjusting impeller clearances often restores a pump and machinery unit to near-factory specifications.

Cavitation creates distinctive pitting on the impeller surface. It happens when vapour bubbles form in the low-pressure area of the pump and then collapse violently. This action eats away at the metal. A damaged impeller cannot lift the fluid effectively. The smooth hydraulic channels become rough and pitted.

Restoring this surface finish is critical for pump and machinery longevity. Friction increases, and performance plummets. We check for this damage during every inspection. Identifying the cause of cavitation is just as important as fixing the damage.

Testing reveals the scope of the repair needed. It typically falls into two categories for your pump and machinery:

Our goal is to return your pump and machinery to a reliable state. We focus on cost-effective repairs that extend the asset’s life rather than immediately suggesting a replacement.

You cannot manage what you cannot measure. A performance test is useless if your gauges give you wrong data. Many sites rely on old, vibrating pressure gauges that have not been checked in years. This leads to false confidence. You might think your pressure pump is failing, but the gauge is simply stuck. Alternatively, you might think the system is fine while the pressure is dangerously high.

Pumpworks offers calibration and verification services. We verify that your on-site flow meters and pressure gauges read correctly. This is particularly important for our clients in the Food & Beverage and Chemical sectors. A flow meter reading incorrectly in a dosing application can ruin a batch of product. It creates hygiene risks and quality control failures. We ensure the instrumentation supporting your pump and machinery tells the truth. Accurate data is the foundation of any good maintenance plan.

Clients often ask us where the testing should happen. How to test pump efficiency? The answer depends on the accuracy you require. There are two main approaches. You can test in the field, or you can test in our workshop. Each has a place in a maintenance strategy. However, the results differ significantly in quality and depth.

Field testing provides a rough health check. We use portable flow meters and clamp-on pressure gauges. This method is good for a quick snapshot. It minimises disruption because we do not remove the pump. However, site conditions are rarely perfect. Turbulence in the pipes or lack of straight pipe lengths can distort sensor readings.

It is useful for spotting major trends, but it lacks the precision needed for fine-tuning. We recommend this for general monitoring of your pump and machinery assets.

We highly recommend workshop testing for critical assets. We strip the unit down, inspect it, and then test it on our rig. This eliminates all external variables. The water is clean, the pipe runs are straight, and the instruments are laboratory-grade.

You receive a certified report detailing exactly how the pump performs. This is the “WOF” standard we advocate for. Send your pressure pump to us during the shutdown. We will return it with a clean bill of health and a performance curve you can trust.

The start of the year is your opportunity to reset. You should plan your maintenance strategy now to ensure consistent output. Here is a simple checklist to help you prioritise your pump and machinery maintenance:

We can turn these units around efficiently to ensure you proceed with reliable equipment. Proactive maintenance costs far less than an emergency call-out during peak production.

We stock the necessary spare parts for Graco and other major brands to ensure quick service. Trusting your equipment to Pumpworks means trusting a team that values your uptime. We treat your pump and machinery as if it were our own.

Efficiency is not an accident. It requires regular testing, precise maintenance, and a partnership with experts who understand your needs. A pressure pump running at peak performance saves energy and reduces stress on your team. Do not let inefficient equipment drain your profits. Use the upcoming shutdown to get the facts about your pump and machinery. We are ready to help you analyse, repair, and optimise your systems.

Contact us today to book your performance test. Let us give you the confidence that your plant is ready for the year ahead. We at Pumpworks are committed to keeping the New Zealand industry moving. We look forward to servicing your pump and machinery and ensuring you get the best flow and pressure possible.

We calculate efficiency by comparing the power going into the fluid (Water Horsepower) against the power supplied to the shaft (Brake Horsepower). The formula involves flow rate, head (pressure), and the specific gravity of the fluid. We measure these variables precisely on our test rig to give you a percentage score. High-quality pump and machinery units should operate close to their designed efficiency point.

What is the purpose of a performance test? The primary goal is to verify that the pump meets its original design specifications. It identifies internal wear, validates repairs, and ensures the unit is safe for operation. It allows you to make informed decisions about whether to repair, replace, or re-rate the pump for a different duty. It effectively creates a benchmark for the health of your pressure pump.

We recommend a full performance test during major services or annually for critical equipment. If a pump serves a non-critical role, you might test it every two years. However, you should test immediately if you notice a drop in discharge pressure or flow. Regular testing of your pump and machinery prevents unexpected failures and keeps your energy consumption optimised.

Address: 16/10 Olive Road, Penrose, Auckland 1061

Phone: 0800 215 104

Email: sales@pumpworks.co.nz