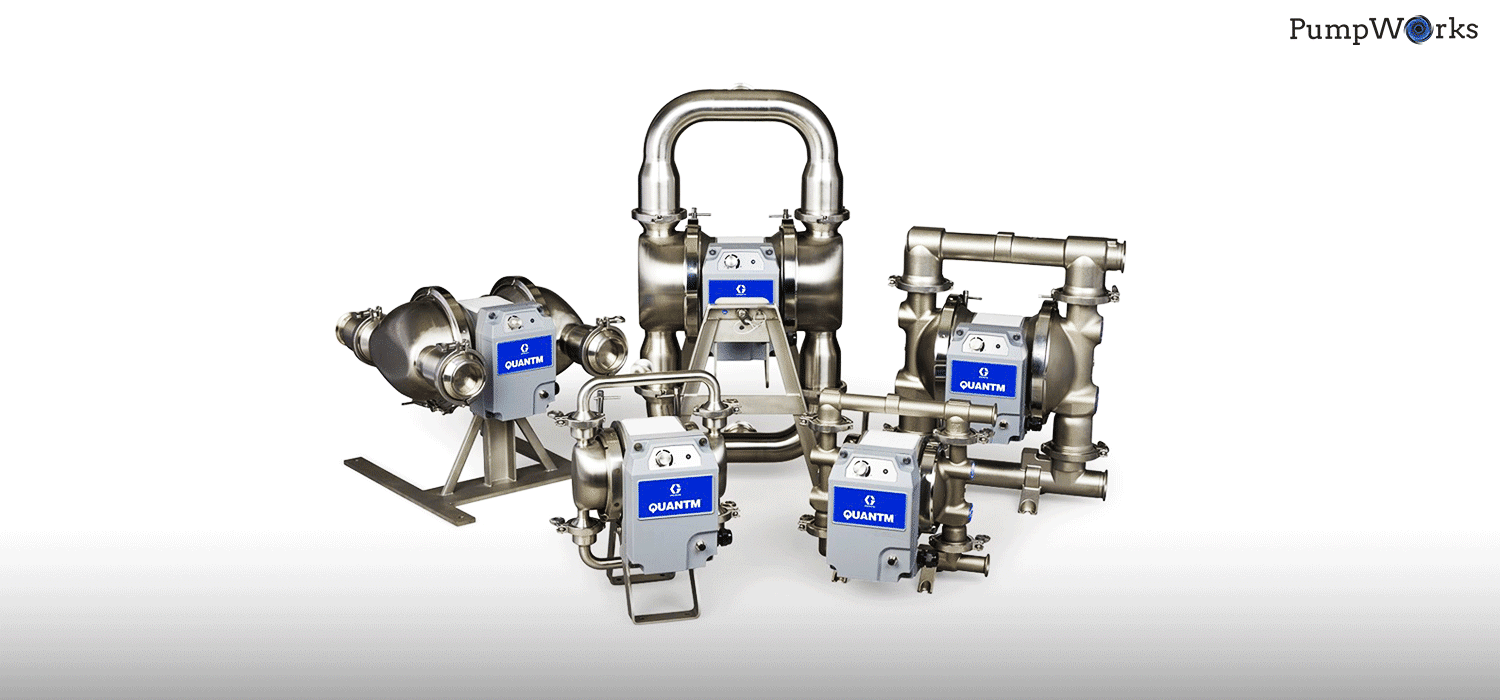

Industrial pump systems are key to productivity in New Zealand. It’s for this reason that a lot of our client base use GRACO pumps. After all, they are built for tough jobs, but they still need regular preventive maintenance to stay reliable.

Certified maintenance schedules help keep your systems running smoothly and get the most value from your investment.

At PumpWorks, we help operators keep their GRACO systems running well, avoid unexpected breakdowns, and make equipment last longer. Preventive servicing is more than just ticking boxes. It means making sure every part works as the manufacturer intended, which protects both efficiency and your warranty.

In this article, we’ll show you:

A certified preventive maintenance plan is a structured servicing program based on GRACO’s OEM standards. Each plan is designed to keep pumps operating at peak condition through regular inspections, testing, and timely replacement of wear components.

Certified plans include:

This process keeps your pumps performing well and helps prevent early wear that can happen if maintenance is skipped or not done by certified experts.

Preventive maintenance is simple: regular care helps you avoid big problems. For GRACO pumps, this means keeping flow steady, pressure correct, and all parts working properly, even when the pumps are used a lot.

Certified schedules include:

When technicians keep an eye on how your pumps are running, they can catch problems early. This helps you avoid costly emergency repairs and production delays that come with waiting until something breaks.

A certified maintenance plan focuses on three main pillars: performance benchmarking, diaphragm operation cycle tracking, and fluid compatibility assessments.

Technicians record baseline performance metrics, including flow rate, suction pressure, and discharge capacity. Any deviation from these readings helps identify internal wear before visible issues appear.

Every GRACO diaphragm pump has a recommended operation cycle count. Certified maintenance includes cycle monitoring to anticipate when diaphragms or seals should be replaced. This avoids rupture-related failures and costly shutdowns.

PumpWorks technicians verify that each unit’s seals, diaphragms, and valves remain compatible with the fluids being pumped. Chemical mismatch is one of the main causes of early seal degradation, and OEM guidance helps prevent this.

Together, these steps help your system meet GRACO’s standards and keep production running smoothly, cycle after cycle.

Regular calibration ensures each GRACO pump maintains operation to specification. During services, technicians compare system data against factory reference tolerances.

Calibration also helps your pumps use less energy by keeping them efficient. Even small changes in pressure or suction can make pumps use more power and cost more to run.

Certified technicians trained to GRACO’s global standards use precision instruments for these checks. Each service includes a detailed health report for every pump, which is valuable for compliance and warranty claims.

The diaphragm is the heart of most GRACO air-operated pumps. Each model has a defined cycle limit, measured in millions of strokes, before a replacement is advised. Ignoring these limits leads to performance loss or complete failure.

By keeping an eye on diaphragms and seals, we help stop leaks, contamination, and costly clean-ups before they happen. Certified maintenance plans spot wear early, so your operations stay safe and clean.

A GRACO pump that gets regular care will stay reliable for much longer than expected. The right maintenance plan helps you get better results now and keeps your equipment in good shape for years to come.

Certified plans are designed for real-world conditions, helping New Zealand businesses avoid expensive downtime and keep production on track. This approach brings real, measurable benefits.

Reactive maintenance means fixing things after they break. Preventive maintenance means taking care of issues before they cause trouble. The difference shows up in your costs, downtime, and risk.

With certified preventive servicing, you can schedule maintenance to fit your production, not disrupt it. If a single seal fails in a GRACO pump, it could stop a whole filling line and affect thousands of products. Preventive care helps you avoid that kind of risk.

Warranty coverage is one of the main reasons to follow OEM-certified maintenance programs. GRACO warranties remain valid only when equipment is serviced by authorised technicians using approved parts.

Our certified service records show that every job meets GRACO’s standards. This protects you from expensive warranty disputes if something goes wrong.

Preventive maintenance directly reduces failure risks by monitoring each stage of pump performance. For example, diaphragm fatigue or valve obstruction can gradually reduce flow rate long before a shutdown. Certified servicing identifies these issues early.

Key actions include:

These preventive steps reduce downtime and interruptions, helping manufacturers keep production steady. The biggest benefit of a certified plan is knowing your equipment will keep running smoothly. This is how to prevent GRACO pump failure with certified service.

PumpWorks follows a clear inspection and reporting process during each service interval.

Each step makes sure your maintenance is fully documented and meets both GRACO’s rules and local industry standards.

Preventive servicing creates measurable reliability gains over time. Reactive repairs often seem less expensive at first, but long-term data tells another story.

These results show that preventive plans actually save money rather than just adding to your costs.

We build our certified maintenance programs in close partnership with GRACO. Every plan uses factory-approved parts, precise tools, and skilled technicians.

At PumpWorks, we see ourselves as part of your team. Our goal is to keep your GRACO systems working just as they should.

In New Zealand’s manufacturing and processing industries, downtime can quickly impact your production goals. Whether you run a dairy, paint, or chemical plant, pumps are at the heart of your operations. Preventive maintenance keeps every GRACO pump dependable, even with constant use.

When you stick to certified maintenance schedules, you can plan with confidence. You get reliable performance without losing valuable production time.

Preventive maintenance isn’t just a technical task; it’s a way to protect your budget. When equipment fails early, it can mean expensive replacements. A certified plan helps you avoid those surprises.

For many of our clients, the savings from preventive maintenance are much greater than the cost of regular servicing.

We support facility managers, engineers, and procurement teams all over New Zealand who depend on GRACO pumps daily. Our preventive maintenance programs fit your production needs and keep every system up to OEM standards.

We do more than just maintain your equipment. We build trust by delivering reliable service that always meets industry standards. Call us today and we’ll sort you out!

Address: 16/10 Olive Road, Penrose, Auckland 1061

Phone: 0800 215 104

Email: sales@pumpworks.co.nz