Service facilities rely on GRACO.

Companies that handle liquids/fluids daily value reliable, accurate equipment that maintains smooth output. Graco meets that need by delivering products that work well under tough conditions and high demand.

This reliability saves downtime and boosts output for many businesses. If you are looking for reliability, accuracy, as well as a proven track record with a backed reputation, then GRACO needs to be your number one choice.

The brand’s commitment to solid construction has earned respect across different markets. Because of that, many decision-makers place Graco high on their list for dependable equipment. This guide will help you see why so many businesses and industries trust Graco’s pumps and their solutions.

It can be helpful to know how a manufacturer gains trust across borders. Many buyers prefer a brand with a clear history and a strong focus on customer needs.

Graco started in the United States. Over time, it widened its customer base through a steady growth strategy. Today, it is seen in production floors, automotive plants, and building projects around the globe.

This presence shows the brand’s ability to serve many industry sectors. While many products still carry American roots, Graco has broadened its network to reach far beyond its home base.

Some models come from the United States, while others may be produced elsewhere. However, strict standards are upheld in all their factories, which results in long-lasting performance.

Strong inspection and testing routines help each item provide accurate pressure control and reliable output. This attention to detail gives people confidence that their pumps will deliver stable service for years.

The company started in Minneapolis, Minnesota, and it built on early achievements to reach other markets. As demand grew, Graco formed links with distribution channels in many countries.

That strategy helped to create a name that is now recognised in projects around the world. By adding new pump models and services, Graco continues to support various businesses with consistent products.

Graco focuses on pumps and fluid management products. It serves factories, paint workshops, oil and gas sites, and other technical fields. The lineup includes pneumatic and electric options for spraying, lubricating, and transferring fluids.

This targeted effort in fluid handling provides practical tools for industry that either need to move fluids or need consistent flow control. Users find it easier to handle jobs from large volume fluid manufacture to lubrication tasks and or difficult medium applications where GRACO have the right equipment for the task at hand.

Graco invests in research and refined assembly methods. Firms across the globe often cite this brand as a top choice for demanding jobs.

The name carries a strong connection with fluid handling solutions that deliver stable output. Many clients use Graco products because they work! If an application requires predictable flow rates, smooth applications or is simply a difficult medium to move, GRACO has the solution.

Graco products include many wear-resistant parts. This helps them provide years of trouble-free use as long as you carry out pump servicing and follow the recommended guidelines.

Many owners keep the same pump in service long after the initial purchase. This track record appeals to production managers who want fewer equipment swaps and stable output for daily tasks. Because of that, some customers refer to Graco pumps as a wise investment for any plant aiming for minimal downtime.

Finding the right model can make a real difference in daily operations. Different liquids and flow rates call for different pump setups.

Several options are available to match diverse needs. Before finalising a pump selection, businesses often look at the required flow rate, fluid viscosity, desired pressure, and the environment where the pump will operate.

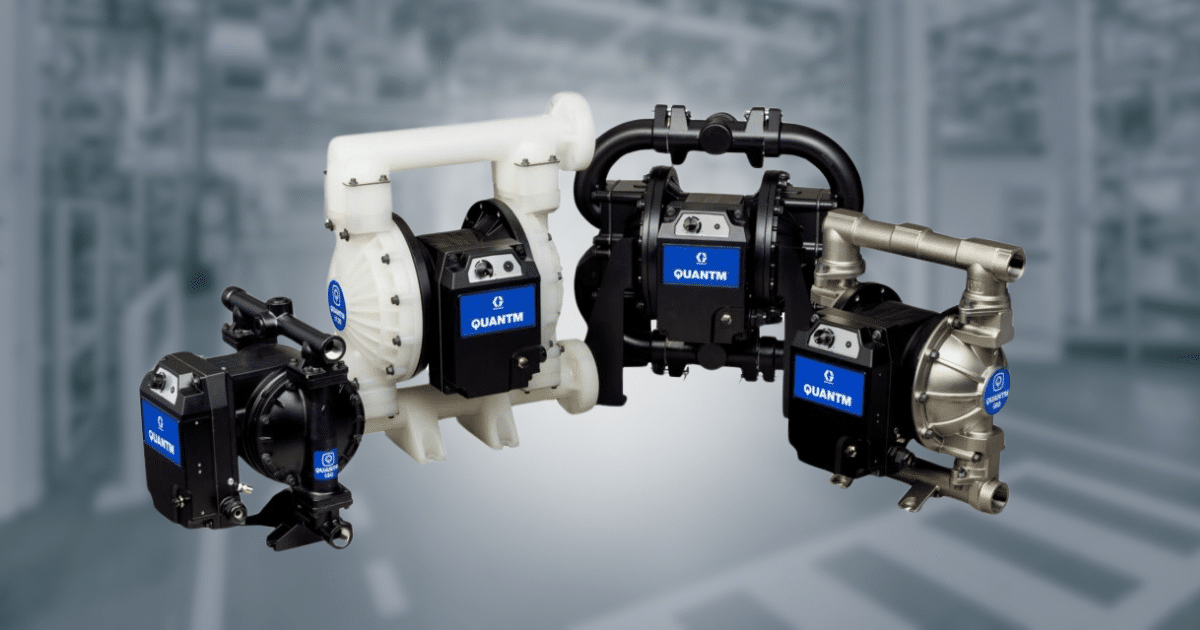

Graco’s diaphragm pumps are designed for industrial and chemical transfer applications. Our chemical and industrial diaphragm pumps come in pneumatic and electric options, with many flow rates and sizes.

Both metal and plastic housings can easily handle corrosive and abrasive fluids. All of our industrial diaphragm pumps are thoroughly tested before they leave our factories.

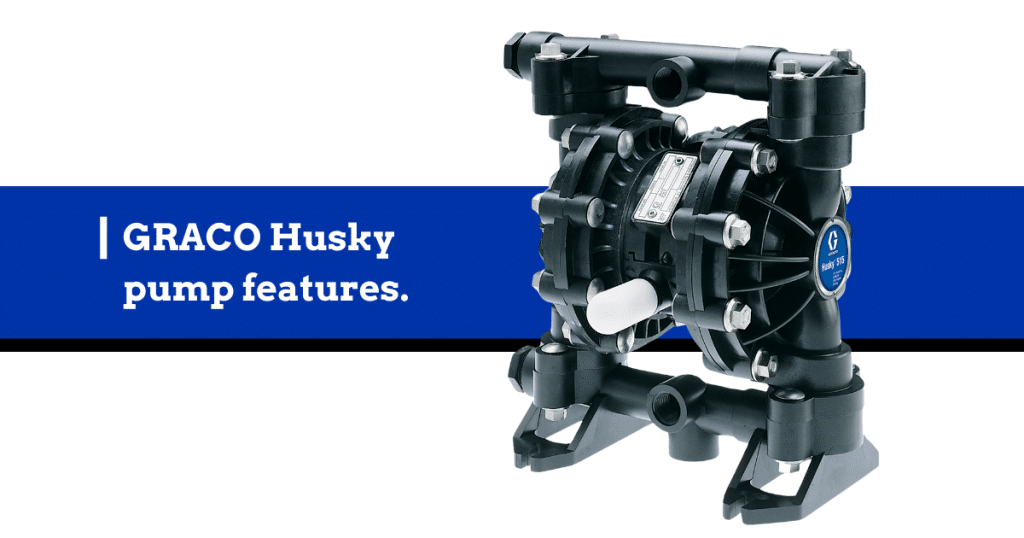

Designed with fewer parts than competitive pumps, Graco’s air-operated double diaphragm pumps feature our stall-free, low pulsation air valve, which is externally accessible, ensuring rapid changeovers and minimum downtimes.

Graco’s electric double diaphragm pumps (EODD) are ideal for applications that require low pulsation and a smooth flow. Our energy-efficient electric drive reduces energy consumption up to 5x compared to traditional air-operated diaphragm pumps.

Each pump is ruggedly constructed to resist corrosion and deliver a long, trouble-free product life.

Graco’s SoloTech Peristaltic Hose Pump design utilises a single roller that compresses an engineered hose through a full 360 degrees of rotation. This innovative design means longer hose life when pumping caustic, abrasive, or sensitive materials for metering or transfer.

Graco’s long-lasting pneumatic and hydraulic ink pumps are ideal for the most difficult inks and other high-viscosity fluids. Expect extended life with these ink transfer pumps, which feature an enclosed, dual-seal wet cup design. With our hydraulic piston pumps you can evacuate directly from buckets, bins or drums. Our pumps are ideally suited to most ink manufacturing and printing applications.

With higher pump pressures and flow rates, Graco priming piston pumps handle a broad range of inks and high viscosity fluids with ease. These Graco-designed pumps offer durability, power and reliability for any ink manufacturing or printing application. Choose from two reliable motor options: pneumatic or hydraulic, each capable of generating high pressures to meet your manufacturing demands.

Graco has been designing and building modern lubrication equipment and systems that serve the in-plant manufacturing industry for decades. Our newest generation of automatic lubrication equipment is the result of years of collaboration with our customers and partners to engineer high-quality, reliable systems that stand above the rest.

These serve heavy machinery, plant maintenance, and assembly lines. They deliver a measured amount of grease or oil, which can save equipment from wear and unplanned downtime. Regular lubrication assists in keeping parts moving smoothly.

Graco Lubrication Equipment Overview

These come into play in factories, chemical mixing sites, and food production lines. They move liquids from one container to another with minimal spillage. Many users choose Graco pumps of this type for both safety and cleanliness in sensitive areas.

300570EN-M Process Equipment Brochure

Power use has become a major concern in various industries, especially when profit margins are tight. A more efficient unit can help reduce overheads and protect the environment.

The brand has developed certain electric diaphragm pumps with an advanced design. For example, the QUANTM series can cut energy use by up to 80% compared to older pneumatic equipment. For many production sites, a small drop in power use can amount to large yearly savings.

Less energy usage means fewer emissions from power generation. When companies adopt more eco-friendly equipment, they can reach their environmental goals faster. Improved pump designs also lower noise, which can result in a more comfortable workspace. These practical perks help businesses stand out in a market that looks for responsible practices.

Companies that handle liquids choose gear that can stand up to frequent use. Graco’s track record often comes up when reliability and cost-effectiveness are priorities.

They use carefully chosen materials and test each model extensively. By using precision-machined parts, these units can handle harsh fluids or heavy workloads.

This attention to each stage of production results in fewer malfunctions once the pump is up and running. Consistent performance also helps with pump troubleshooting, as the design tends to be straightforward for technicians to maintain.

Oil and gas plants, food and beverage, manufacturing, and assembly lines often select Graco pumps because of their steady output and reliability over the years. The brand has stayed close to users’ needs by offering spare parts, service options, and easy-to-access product data.

Many factories trust this gear for mission-critical tasks that cannot afford a breakdown. The combination of proven construction and responsive support has placed Graco among the top picks for pumping solutions.

We serve as pump suppliers who carry a range of Graco models to suit local businesses. Our team has seen how details such as a difficult medium, temperature range, fluid thickness, and space constraints can affect a pump selection. We offer guidance that helps you narrow down the model you need.

At PumpWorks, we not only supply but also provide In-House pump servicing, spare parts, and upgrades that keep your operations on track. We provide suggestions based on your specific site’s requirements, workflow and budget. That personal approach can reduce downtime and improve long-term outcomes.

Graco pumps can help you improve efficiencies, reduce maintenance costs, and boost daily output. The brand’s history and global recognition reflect a steady focus on quality. Equipment that lasts for years can spare you from the hassles of frequent replacements. By choosing a proven product, you can focus on tasks that increase productivity.

We know that pump efficiency and reliability matter for a stable operation. That is why we make it a priority to keep a selection of Graco products in our Auckland-based inventory.

As a New Zealand-based business, we speak your language and understand the local needs. We value relationships and want you to have the best pumping solutions for your plant or workshop. Our team stands by with advice about sizing, configuration, and spare parts. That support extends to pump trouble shooting or any maintenance queries that pop up.

Let us help you match the right Graco model to your everyday needs. We invite you to get in touch or stop by our facility to view our collection of Graco pumps. Our goal is simple—keep your business flowing smoothly and set you up with a pump built to last! At PUMPWORKS, We Are “Part Of Your Team”

Address: 16/10 Olive Road, Penrose, Auckland 1061

Phone: 0800 215 104

Email: sales@pumpworks.co.nz